With technological advancement and the innovations in modern equipment, the construction industry has come a long way with reduced build times and optimised cost. One such example is modular construction. It is increasingly finding its place as a viable alternative to traditional construction process, and that too, with better quality, strength and durability. The conventional process is not only labour-intensive and costly but also poses multiple risks in terms of project deliverability, safety, productivity and supply chain efficiencies. On the other hand, Modular construction is much faster & efficient and takes only up to half the amount of time usually required for on-site construction. Since most of these units are built offsite, all that’s left is delivering the modules and installing them in place, along with finishing touches like wiring, plumbing, painting, etc.

Fibre cement boards are one of the innovations in modular prefabricated construction. Made of fibre reinforced with cement, the material is even stronger than concrete. Together with a carefully planned production process, fibre cement makes it possible to develop strong and long lasting construction materials. The fibre cement board is a cost effective and time saving solution for construction of dry walls. It has all the advantages of masonry wall with added qualities for preferred construction.

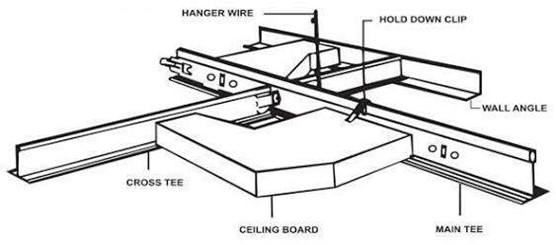

Fibre cement boards are easy to install and prove to be a better substitute for conventional walls and any even other dry walls solutions. They are eco-friendly which make the prefabricated structures safe and comfortable to live. They act as sound absorbing panels providing conducive work environment and are also ideal for use in residential constructions like false ceiling for hall, rooftop extensions, storage rooms, exterior wall cladding, sentry post, cottages, farm house, site-offices and many others. Other commercial applications include offices, labors quarters, transit camps rehabilitation centers, schools, health care centers, kiosks, etc. The list is endless. Let us see what benefits fibre cement sheets in particular and modular construction in general has.

Also Read: Set up A Quick & Eco-Friendly Fibre Cement House With EcoPro

The Benefits of Modular Construction

Reduced Construction Time

As stated earlier, modular projects can be completed in only up to half the time as traditional construction projects. This means that the speed of constructing a modular building is doubled as compared to the traditional methods. With modular construction, the traditional steps like site foundation work can be done simultaneously with the modular units being constructed in the factory. Units like walls and ceilings, which are simply sheets to be aligned together, can directly be transported to the site and assembled on the spot.

Saves Labor Cost

Modular units are stacked like lego blocks to form one whole unit or building. Off-site construction allows work to be done in a controlled environment, causing fewer headaches and higher efficiency. Since modular construction is performed in controlled conditions, much of the labor comes from skilled factory workers who can produce more than on-site construction crews and tradesmen, at a lower cost. This efficiency and labor cost savings can save money on the project, as a whole.

Uniform Quality Materials Means Longer Life

Factory made pieces mean no more relying on the contractor to ensure proper construction. Controlled construction ensures consistency and quality. Building materials are safe, away from moisture or the elements—meaning that the materials are at their peak quality.

Little to No Impact on Current Business

Modular construction removes about 80% of construction activity from the site. So if you’re expanding your business, you don’t have to be concerned about construction negatively impacting your place of work.

If you are impressed by the prospect of modular construction and are looking to integrate Fibre cement elements into your building, contact EcoPro now on info@ecopro.co.in or +91 20 2645 8888!