In the world of construction, selecting the right material is crucial for ensuring both immediate performance and long-term value. Fibre cement boards have emerged as a popular choice for many builders and architects, thanks to their exceptional versatility, strength, and cost-effectiveness. In this blog, we’ll explore why these boards are not just a practical solution but a financially sound choice for long-term use.

- Durability and Longevity

Fibre cement boards are known for their durability and longevity. It’s manufactured from a combination of cement, sand, and cellulose fibre, flyash which results in a material that can withstand the toughest environmental conditions. Here’s how their durability leads to long-term savings:

- Weather Resistance: Fibre cement boards can handle extreme temperatures, heavy rains, and strong winds without warping or deteriorating. Their sturdy composition prevents warping, swelling, or cracking, ensuring the material remains structurally sound for many years, significantly reducing repair and replacement needs.

- Pest Resistance: Fibre cement boards are naturally resistant against the termite and pest attack. This significantly reduces the cost of pest control treatments and replacements.

- Fire Resistance: Fibre cement boards are naturally non-combustible, offering excellent fire protection. This adds to their durability and reduces fire-related risks and maintenance expenses.

- Low Maintenance Costs

Traditional materials often require regular maintenance—wood needs painting, sealing, and protection from rot, while vinyl may crack or fade over time. Fibre cement boards, on the other hand, require minimal maintenance. Here’s why:

- Paint Retention: Fibre cement boards come with stain which deeply absorbed into the material. This prevents fading over time, allowing the boards to retain their rich colour and finish for years without the need for frequent maintenance.

- Moisture Resistance: Since fibre cement boards like ECOPRO PLUS comes with special coating that don’t absorb water, don’t suffer from swelling, cracking, or mildew. This eliminates costly maintenance related to water damage, especially in humid climates.

- Energy Efficiency

Fibre cement boards known for its excellent insulation properties, which contributes to better energy efficiency in buildings. This leads to reduced heating and cooling costs, especially in regions with extreme temperatures.

- Thermal Insulation: Fibre cement boards highly resistant to thermal or heat transfer, helping regulate indoor temperatures. This lowers the reliance on heating and air conditioning systems, resulting in reduced energy bills.

- Versatility and Design Flexibility

One of the reasons fibre cement boards are cost-effective is their versatility. They can mimic the look of other, more expensive materials, like wood or stone, without the added costs.

- Aesthetic Flexibility: Fibre cement boards come in various textures and finishes, like PEBBLES, WAVES, AQUATIC, STONE, BRICK, WOODEN TEXTURE.

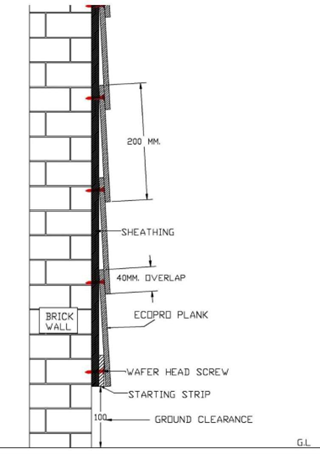

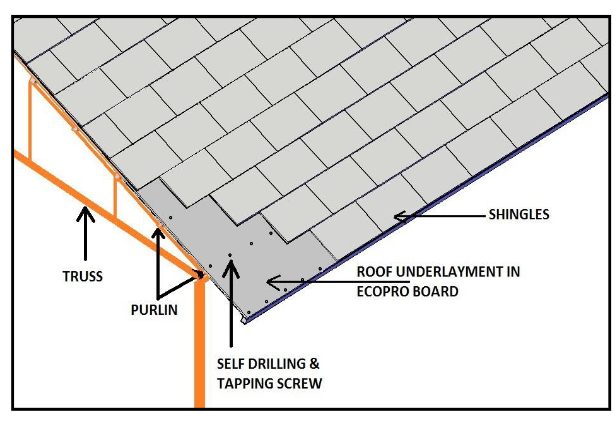

- Variety of Applications: Fibre cement boards can be used for exterior cladding, interior walls, façades, ceilings, roof underlay, kitchen cabinets, mezzanine floor and even flooring, reducing the need to purchase multiple materials for different applications. This multifunctionality helps in cutting overall construction costs.

- Environmentally Friendly and Sustainable

In today’s eco-conscious world, choosing sustainable building materials is not only better for the planet but also for long-term financial savings.

- Sustainability: Fibre cement boards are made from sustainable materials like cement, sand, cellulose fibres, and recycled components like fly ash. They don’t emit harmful gases, contributing to a healthier indoor environment. Moreover, their long lifespan means fewer replacements, leading to reduced material consumption and waste.

- LEED Credits: Fibre cement boards can help earn LEED (Leadership in Energy and Environmental Design) certification credits for green buildings. This certification can increase property value and offer financial incentives, making them a cost-effective option for environmentally conscious builders.

- Cost of Installation and Lifecycle Cost

Though the initial installation cost of fibre cement boards is less compared to some other materials.

- Low Replacement Costs: Fibre cement boards last for decades without the need for replacement, unlike materials like wood or vinyl which may need frequent changes.

- Fewer Repairs: Their strength and resistance to damage mean fewer repairs over time, saving on labor and material costs associated with maintenance.

- Value Addition: The durability, fire resistance, and aesthetics of fibre cement boards often lead to an increase in property value, making them a wise long-term investment.

EcoPro fibre cement boards from SAHAYDRI INDUSTRIES LIMITED stand out due to their low upkeep requirements, durability, and energy-saving properties, making them a cost-efficient option. With additional advantages like fire safety, pest resistance, eco-friendliness, and design flexibility, they are a perfect choice for those looking for both performance and savings in construction. Whether for builders, architects, or homeowners, EcoPro fibre cement boards represent a smart, long-term investment.